Basics

In hydroponics and the associated aquaponics, there are different methods to supply plants with nutrients. These can be divided into active and passive systems. Passive systems have the advantage of being independent of a power supply. However, their efficiency is lower than that of active approaches.

Passive and Active Hydroponics Systems

Passive hydroponics systems are systems that function without a power supply. In active hydroponics, pumps, aerators, humidifiers, or spray misters are used. These require electricity. Although active hydroponics systems are more complex in setup, they are many times more effective in terms of plant growth due to the oxygen input.

Passive Hydroponics (without electricity)

💧 Wick Irrigation 💧 Kratky MethodActive Hydroponics

💧 Ebb and Flow Systems 💧 NFT - Nutrient Film Technique 💧 DWC - Deep Water Culture 💧 DFT - Deep Flow Technique 💧 Drip Irrigation 💧 Vertical Systems (Tower) 💧 Aeroponics 💧 Fogponics 💧 Media-Bed Systems 💧 Floating-Raft SystemAquaponics

💧 Aquaponics - Plant Cultivation and Fish Farming 💧 Aquaponics - CHOP (Constant Height, One Pump) 💧 Decoupled Systems (DAPS)A brief overview of the most common systems in aqua- and hydroponics

Passive Hydroponics:

Wick Irrigation

The wick system requires no moving parts and no electricity. The plants are cultivated in a substrate that is supplied with the nutrient solution through the capillary action of the "wick". The supply of plants via this system is not very effective. Additionally, the wick can largely lose its nutrient transport properties due to mineral deposits. Another disadvantage is that no extra oxygen is supplied to the roots. The system is technically simple, but plant growth is slower than with other, active, hydroponic systems.

Pro:

- ✅ low acquisition cost

- ✅ no electricity

- ✅ no technology

- ✅ low nutrient consumption

- ✅ low monitoring effort

Con:

- ❌ very low yield

- ❌ slow growth

Passive Hydroponics:

Kratky Method

The Kratky method is a particularly simple form of hydroponics and a variant of deep water culture. Plants grow in net pots placed above a reservoir of nutrient solution. As the liquid level drops, an air gap is created, supplying oxygen to the roots. This passive system requires no pumps or aeration and is therefore very low-cost. The method is particularly suitable for leafy vegetables like lettuce or basil, but less suitable for large-fruited plants.

Pro:

- ✅ very simple and inexpensive

- ✅ no electricity or technology

- ✅ low monitoring effort

Con:

- ❌ limited plant selection

- ❌ lower yield than active systems

- ❌ no long-term use without refilling

Ebb and Flow Systems

Ebb and Flow systems use pumps (4) that flood the plants with the nutrient solution on a timed basis (2). The plants are embedded in a net pot. After the pump is switched off, the excess nutrient solution is returned to the reservoir (1) via an overflow (3). Often a residual amount remains to make the system less susceptible; if the pumps fail, enough water remains in the plant tray since the overflow ensures a minimum water supply.

By raising and lowering the liquid level (2), oxygen is introduced into the root zone, leading to more intensive plant growth. Control electronics must adapt the ebb and flow rhythm to the requirements of the plants.

Pro:

- ✅ low nutrient consumption

- ✅ low water consumption

- ✅ high yield

- ✅ in case of power or pump failure: no crop loss

Con:

- ❌ high acquisition costs

- ❌ power supply needed

- ❌ monitoring effort

NFT

Nutrient Film Technique

NFT or Nutrient Film Technique systems deliver a permanent nutrient flow that surrounds the roots in a thin "film". A pump delivers the nutrient solution to a sloped plane where the plant roots lie and are thus continuously supplied. The constant flow prevents nutrient accumulation.

The design of NFT systems also introduces oxygen into the nutrient solution, e.g., through downpipes or swirling systems. Planting substrate is usually omitted, so the roots have direct access to nutrients and oxygen, allowing them to grow quickly.

A disadvantage is the loss of all plants in case of pump failure or power outage.

Pro:

- ✅ low nutrient consumption

- ✅ low water consumption

- ✅ very high yield

Con:

- ❌ high acquisition costs

- ❌ power supply needed

- ❌ monitoring effort

- ❌ in case of power or pump failure: crop loss

DWC

Deep Water Culture

In Deep Water Culture systems, also known as DWC systems, already rooted plants are placed in a net pot on a floating plate into the liquid reservoir, like a raft. To stabilize the plant, the net pot can be filled with substrate, such as clay pebbles. The roots hang directly in the nutrient solution, which is enriched with oxygen. This is done using an air pump and air stones that introduce very fine air bubbles into the water.

Since the roots are constantly supplied with oxygen-rich nutrient solution, the plants grow very quickly and vigorously. The system is simple and safe; even in a power outage, nothing happens to the plants immediately. Due to the large water reservoir, the system can be left alone for a few days without needing attention.

In the DWC system, plants can also sit on a kind of raft and float on the nutrient solution.

Pro:

- ✅ low nutrient consumption

- ✅ low water consumption

- ✅ very high yield

- ✅ fast growth (Oxygen)

- ✅ in case of power or pump failure: no crop loss

Con:

- ❌ high acquisition costs

- ❌ power supply needed

- ❌ monitoring effort

DFT

Deep Flow Technique

Active Hydroponics: DFT - Deep Flow Technique

The deep flow technique, better known as DFT, is a variant of the NFT technique, also known as Nutrient Film Technique. Instead of a thin nutrient film, the plants are surrounded by a nutrient solution about 2-4 cm high. The basic process is the same and works recirculating.

The Deep Flow Technique (DFT) makes this cultivation system safer because if a pump fails, the roots continue to be supplied. However, the method has not really caught on in the industry, especially with longer/larger systems, because the oxygen supply to the plants can be uneven, leading to uneven plant growth. It is considered an active hydroponics system.

Pro:

- ✅ low nutrient consumption

- ✅ low water consumption

- ✅ very high yield

Con:

- ❌ high acquisition costs

- ❌ power supply needed

- ❌ monitoring effort

- ❌ in case of power or pump failure: crop loss

Drip System

Drip Irrigation

In drip irrigation (Drip System), the nutrient solution is dripped onto the substrate around the plants via a drip line. The nutrient solution flows past the roots, supplying them directly. The excess liquid drains away, supplying oxygen to the root zone in the process.

Non-recirculating system:

In industrial cultivation, non-recovery systems are used to achieve high yields without measurement technology. The plants are always supplied with fresh, consistently adjusted nutrient solution. The nutrient solution is not returned to the cycle to prevent the spread of pathogens. This process consumes more water and unused nutrients are lost. This system does not require nutrient control but relies on experience with nutrient consumption. The system can be run "blindly".

Pro:

- ✅ very high yield

- ✅ fast growth

- ✅ in case of power or pump failure: no crop loss

- ✅ low monitoring effort

Con:

- ❌ high acquisition costs

- ❌ power supply needed

- ❌ high nutrient consumption

- ❌ high water consumption

Recirculating system:

The nutrient solution is fed back into the system, meaning only the nutrients that the plant actually needs are consumed. The flow rate is adjusted to the needs of the plants. However, due to the closed system, nutrient control is necessary to adjust them to the growth phase-dependent consumption. This system requires regular monitoring of nutrient concentration.

Pro:

- ✅ very high yield

- ✅ fast growth

- ✅ in case of power or pump failure: no crop loss

Con:

- ❌ high acquisition costs

- ❌ power supply needed

- ❌ monitoring effort

Tower

Vertical Systems/Towers

Vertical hydroponics uses towers or tubes in which plants grow on top of each other. The nutrient solution circulates from top to bottom. This optimizes space usage, especially for urban farming and indoor gardens. Ideal for lettuce, herbs, and small vegetable types.

Pro:

- ✅ space-saving

- ✅ high yield per area

- ✅ suitable for cities

Con:

- ❌ higher technical effort

- ❌ uneven supply possible

- ❌ power supply needed

Aeroponics

Mist from nutrient solution

In an aeroponic cultivation system, the roots of cuttings or plants do not hang in a liquid but in a mist of nutrient solution. The plants are suspended with net pots into a chamber where the roots are sprayed or misted with nutrient solution via water nozzles / misting nozzles.

Aeroponic systems provide optimal supply to the roots with everything they need to grow; they work very effectively and deliver maximum plant growth and are therefore considered active hydroponics systems. However, the technical effort is high due to the high water pressure required for the nozzles or the misters used. Furthermore, technical measures must be taken to prevent clogging of the nozzles. A disadvantage is that a failure of the misters cannot be tolerated for long by the freely hanging roots.

Pro:

- ✅ very high yield

- ✅ fast growth

Con:

- ❌ high acquisition costs

- ❌ power supply needed

- ❌ high nutrient consumption

- ❌ high water consumption

- ❌ monitoring effort

Fogponics

Fine Mist

Fogponics is a further development of aeroponics. The nutrient solution is transformed into an extremely fine mist (droplets < 5 µm) by ultrasound. The roots absorb nutrients particularly efficiently, leading to very fast growth. However, the technology is sensitive and expensive.

Pro:

- ✅ extremely fast growth

- ✅ very high efficiency

- ✅ low water consumption

Con:

- ❌ very high costs

- ❌ sensitive technology

- ❌ high energy requirement

Media-Bed Systems

Media beds consist of beds filled with substrates such as expanded clay or lava rock. They serve as both a plant bed and a biological filter where microorganisms convert fish waste into plant nutrients. Simple construction, popular in small aquaponics systems.

Pro:

- ✅ simple construction

- ✅ filtration integrated

- ✅ versatile

Con:

- ❌ regular cleaning necessary

- ❌ limited scalability

Raft-System

floating beds / Floating Raft

In the raft system, plants float in styrofoam boards on a large water tank. Their roots hang directly into the nutrient-rich, circulated water. Especially suitable for leafy vegetables like lettuce or spinach, often used in large-scale aquaponics systems.

Pro:

- ✅ stable cycle

- ✅ very good for leafy vegetables

- ✅ high yields

Con:

- ❌ high water requirement

- ❌ large tanks require much space

Fish farming can be combined with all systems that allow separation and control of nutrients through a loop.

Aquaponics

Plant Cultivation and Fish Farming

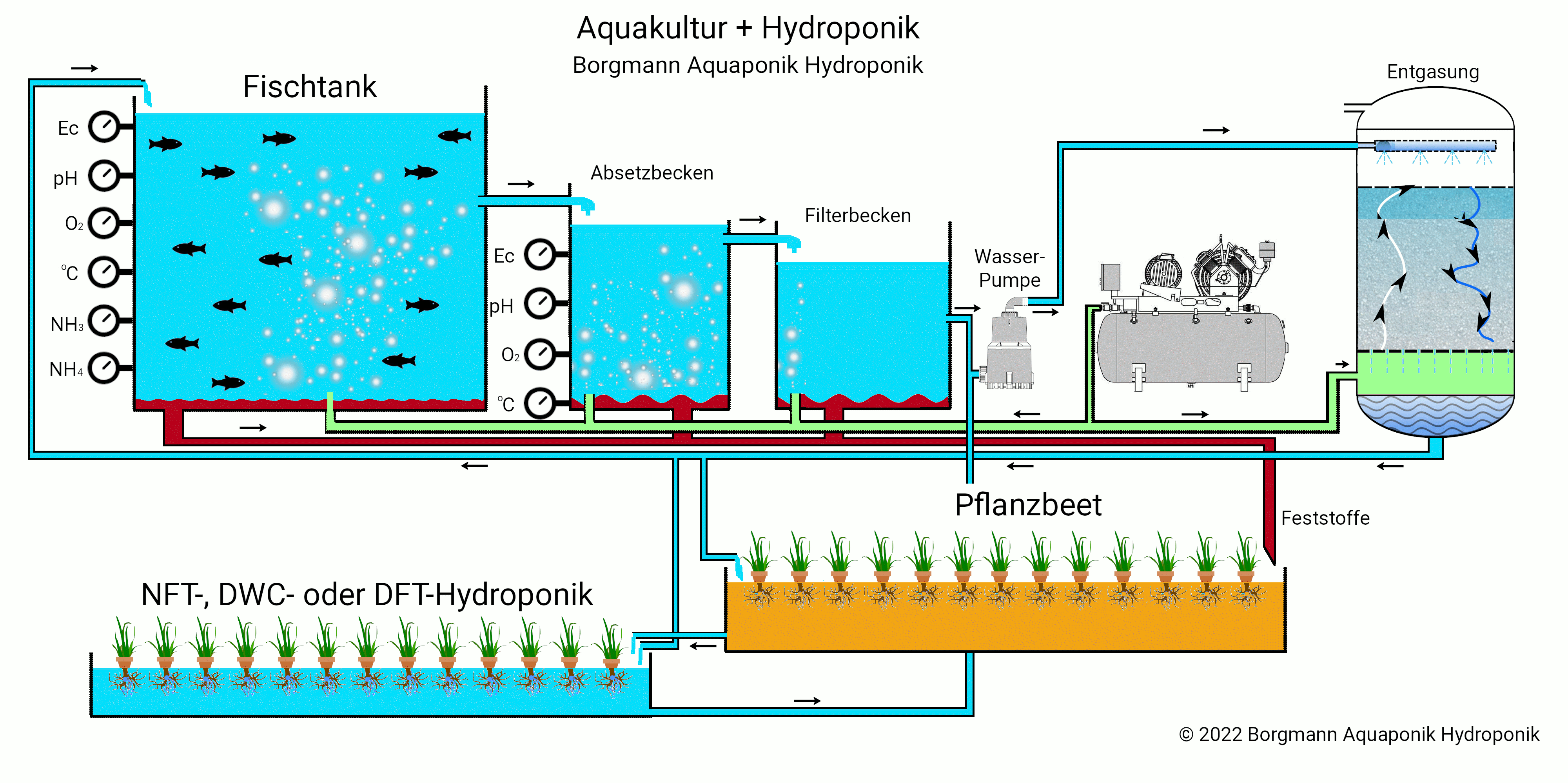

Aquaponics is composed of aquaculture (fish farming) and hydroponics (plant cultivation), meaning two cultivation systems are combined. The excretions from the fish are used to supply nutrients to the plants; they are recycled and serve as fertilizer.

The conversion of excretions into nutrients usable by plants is done with the help of microorganisms. This also simultaneously cleans the water so that it can be returned to the fish tank, providing the fish with good living conditions. Thus, a cycle with a win-win situation is created. In addition to growing lettuce and vegetables, fish are raised as food, or ponds with ornamental fish are kept clean.

Aquaponics CHOP

Constant high, one pump

The decisive advantage of introducing a sump tank is that the water level – especially in the fish tank – remains constant at all times. Only when water is pumped from above into the fish tank does water flow back via the overflow. This means less stress for the fish on one hand, and on the other hand, the tank remains filled with water even if the system fails (e.g., due to a pipe break), since the water level can never fall below the overflow.

Pro:

- ✅ high yield

- ✅ fast growth

- ✅ in case of power or pump failure: no crop loss

Con:

- ❌ high acquisition costs

- ❌ high monitoring effort

Aquaponics DAPS

Decoupled Systems

In decoupled systems (DAPS), the fish and plant systems run separately. Nutrients are transferred from the fish water to the plant system without flowing back. This allows pH, temperature, and nutrient content to be optimized independently. Often used in high-tech systems.

Pro:

- ✅ precise control

- ✅ better scalability

- ✅ higher safety for fish

Con:

- ❌ complex setup

- ❌ high costs

- ❌ high monitoring effort

Context: