Core elements of ecoponics

Use of organic nutrient solutions

In contrast to conventional hydroponic systems, which often rely on synthetic fertilizers, ecoponics uses organic nutrient solutions. These are derived from natural sources such as compost tea, worm compost extract or other organic waste.

Sustainable resource management

Ecoponic systems are designed to use water and nutrients efficiently. By reusing and recycling water and nutrients, the ecological footprint is minimized.

Promoting biodiversity

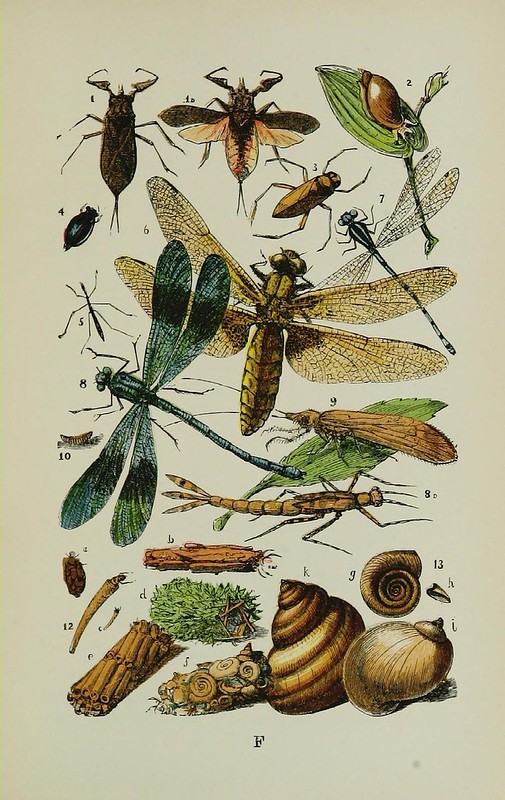

Ecoponics promotes biodiversity by integrating different plant species and creatures (snails, cockroaches, earthworms, guppies, etc) into a system. This can help to control pests and diseases and maintain the ecological balance.

Energy efficiency

By using renewable energy and energy-efficient technologies, ecoponics aims to reduce energy consumption and minimize environmental impact.

Instead of chemical pesticides, ecoponic systems use biological pest control methods such as beneficial insects or biological preparations.

Advantages of ecoponics

- Environmentally friendly: By not using synthetic fertilizers and pesticides, the environment is less polluted.

- Resource-efficient: The efficient use of water and nutrients helps to conserve natural resources.

- Healthy food production: The use of organic nutrients leads to healthier plants and therefore healthier food.

- Promoting sustainability: Ecoponic systems support sustainable agricultural practices and contribute to the preservation of natural ecosystems.

While ecoponics as a concept is gaining momentum, there is less comprehensive scientific literature on it compared to aquaponics and hydroponics. For further information, specialized publications and case studies of organic farms may be helpful. A useful book could be "The Organic No-Till Farming Revolution" by Andrew Mefferd, which describes sustainable farming practices in detail, although it does not focus exclusively on ecoponics.

- Environmental friendliness: By avoiding synthetic fertilizers and pesticides, ecoponics reduces environmental pollution and conserves natural resources.

- Resource efficiency: Ecoponic systems use water and nutrients efficiently, resulting in significant reductions in water consumption and better use of resources.

- Healthy food production: The use of organic nutrients leads to healthier plants and therefore higher quality and more nutritious food.

- Promoting biodiversity: By integrating different plant species and promoting ecologically beneficial organisms, ecoponics contributes to the preservation and promotion of biodiversity.

- Sustainability: Ecoponics supports sustainable agricultural practices that contribute to the long-term conservation of natural ecosystems.

- Reducing waste: Using organic waste as a source of nutrients and reusing water minimizes waste.

- Independence from soil: Ecoponic systems can operate independently of soil quality, allowing cultivation in urban areas and on infertile soils.

Problems in implementing ecoponics

- Imbalance: It can be difficult to provide the correct amounts and ratios of organic nutrients because they are more variable than synthetic fertilizers.

- Deficiency symptoms: Organic nutrients must be in forms that are available to plants, which is supported by microbiological processes that do not always occur consistently.

- Contaminants: Organic nutrients can increase the risk of contaminants in the water system, which can lead to algae growth and blockages.

- Microbial contamination: Improper handling of organic material can lead to the proliferation of undesirable microorganisms that can cause plant diseases.

- Biological pest control: The use of natural enemies and biological preparations can be less predictable and more effective than chemical agents.

- Diseases: Organic systems may be more susceptible to certain plant diseases that are difficult to control.

- System complexity: Ecoponic systems are often more complex than traditional hydroponic systems and require a higher level of knowledge and technical expertise.

- Maintenance: The systems require regular maintenance and monitoring to ensure optimal functioning.

- Initial costs: The initial investment to set up an ecoponic system can be high, especially when sustainable and energy-efficient technologies are integrated.

- Running costs: Running costs for maintaining biological systems and obtaining organic nutrients can also be high.

- Expertise: There is a need for specialized knowledge and training to operate the system effectively and solve problems.

- Experience: The lack of widespread experience and best practices can make implementation difficult.

- Locally adapted solutions: Each region has different climatic and ecological conditions that require tailor-made solutions.

- Availability of resources: The availability of high-quality organic materials may vary regionally and influence implementation.

Here are some keywords about ecoponics and its implementation

- Compost tea

- Worm compost extract

- Plant extracts

- Fermented organic matter

- water recycling

- circular economy

- resource efficiency

- rainwater use

- Mixed cultures

- Biodiversity promotion

- Companion planting (plant communities)

- Ecological beneficial organisms

- Renewable energies (solar, wind)

- Energy-saving lighting (LED)

- Energy management

- Heat recovery systems

- Promotion of beneficial organisms

- Biological preparations

- Integrated plant protection (IPM)

- Plant extracts against pests

- Vertical farming

- Modularity

- Automation and sensors

- Substrate selection (e.g. coconut fibres, peat moss)

- Permaculture principles

- Zero waste principles

- Circular systems

- Environmental impact assessment

- Community Gardens

- Educational Programs

- Research and Development

- Public Relations

Context:

Setting up an Ecoponic System

The setup of an ecoponic system largely determines how stable, low-maintenance, and cost-efficient it will operate later. While the basic principles remain the same – a fish tank, a biological filter, plant modules, and a closed water cycle – the construction methods differ significantly in effort, material requirements, and costs. The following sections introduce the most common variants in a practical way, helping you make a well-informed decision for your own entry into the field.

Building an ecoponic system is not just a technical project, but rather an attempt to recreate a functioning small ecosystem. The key lies in allowing organic diversity while gently supporting it with technology.

What works on a small scale can later be expanded: additional modules, more plant species, renewable energy sources. But every large cycle begins with a small tank, a few plants – and the willingness to let the system grow.

1. Basic System Elements

Regardless of construction style, ecoponic systems consist of the same core components:

- Fish tank: provides nutrients through excretions, size depends on desired stocking density.

- Mechanical-biological filter: converts organic waste into plant-available nutrients.

- Plant modules: absorb nutrients, clean the water, and form the visible cultivation area.

- Pump and pipes: keep the water cycle moving.

- Aeration: supplies oxygen to the water and root zone.

For beginners, it is advisable to combine these elements as simply as possible and to rely on robust components.

2. Construction Variants Compared

a) Media Bed Systems

In the media bed, plants grow in beds filled with substrate. Expanded clay, lava granules, or gravel not only provide support for the roots but also offer large surfaces for microorganisms. The water is flooded and then drained again (flood-and-drain).

Practice: Ideal for small systems starting from 300 liters of water and 1–2 m² of bed area.

- Advantages: simple construction, good filtration performance, high stability.

- Disadvantages: beds are heavy and space-intensive, cleaning is laborious.

- Costs: approx. €400–800 for a small starter system (fish tank, pump, two 1-m² beds, filter).

- Workload: 1–2 hours per week (control, maintenance, cleaning).

b) Deep Water Culture (DWC)

In DWC systems, plants float on water channels or tanks in styrofoam rafts. The roots hang directly into the water, which must be permanently aerated. DWC is widely used in aquaponics, also for large-scale production.

Practice: Typical are tanks 20–30 cm deep with floating trays.

- Advantages: easy to handle, plants are easy to insert and harvest.

- Disadvantages: oxygen supply is critical, risk of root diseases in case of imbalance.

- Costs: approx. €600–1200 for a small system (300-l fish tank, 2–3 DWC modules of 1 m² each).

- Workload: 1–2 hours per week, plus monitoring of aeration.

c) Nutrient Film Technique (NFT)

In the NFT technique, a thin film of water flows through channels or pipes where plants sit in net pots. The roots are continuously supplied with water and oxygen. NFT is particularly suitable for fast-growing plants such as lettuce or herbs.

Practice: Typical are PVC pipes (Ø 100 mm) or rectangular channels, 2–4 m long.

- Advantages: space-saving, small water volume in circulation, easy access to plants.

- Disadvantages: sensitive to interruptions (pump failure), risk of clogging due to organic material.

- Costs: approx. €500–1000 for 4–6 channels, fish tank, and filter.

- Workload: 1–2 hours per week, higher susceptibility to failures.

d) Vertical Systems

Vertical systems use the space upwards: plants grow in columns or wall modules, water trickles from top to bottom. This construction method is particularly interesting for urban spaces as it requires little floor area.

Practice: Use of PVC pipes or plastic columns with planting holes.

- Advantages: high space efficiency, attractive for demonstration setups and urban farming.

- Disadvantages: technically more complex, uneven supply to individual plants possible.

- Costs: starting at approx. €800 for a small system (6–8 columns with fish tank and pump).

- Workload: 2–3 hours per week, requires increased monitoring.

3. Selection and Recommendation

For beginners, the media bed system offers the greatest stability and the lowest technical hurdles. Those working with limited space may opt for NFT, but must expect higher monitoring effort. DWC is suitable for large-scale cultivation and research projects, while vertical systems are particularly attractive for urban farming, where every square meter counts.

Conclusion: Setting up an ecoponic system requires choosing a construction method that suits both the location and your own goals. With investments between €400 and €1200, functional entry-level systems can already be realized. What matters most are not just the costs, but above all patience, observation, and the willingness to understand the system step by step.

Context:

In established aquaponics systems, plants and microorganisms form a complex symbiosis that represents the core of the closed-loop cycle. This article examines the practical aspects of this interdependence.

Plant Selection for Optimal Loop Stability

Plant selection is based on nutrient requirements, root systems, and growth speed:

Heavy Feeders with Filter Function

Pak Choi (Brassica rapa subsp. chinensis) is particularly suitable due to its high nitrate absorption capacity. The shallow root systems are suitable for NFT systems (Nutrient Film Technique).

Water Spinach (Ipomoea aquatica) shows particularly efficient heavy metal binding in studies and is suitable for systems with higher fish stocking density.

Medium Feeders for Deep Beds

Black Salsify (Scorzonera hispanica) develops deep taproots that transport oxygen to deeper substrate layers, thereby preventing anaerobic zones.

Horseradish (Armoracia rusticana) shows antimicrobial effects against pathogenic germs in the water, especially at higher water temperatures.

Microbial Control in Practical Operation

Microbial colonization is specifically controlled through substrate choice, aeration, and plant combination:

Nitrification Cascades in Different System Components

In practical aquaponics systems, nitrification occurs not only in the biofilter but is distributed across several components:

- Plant root systems: Colonization with nitrifying bacteria (Nitrosomonas, Nitrobacter) and heterotrophic bacteria that break down organic complexes.

- Specialty substrates: Lava granules with high specific surface area (≥ 300 m²/m³) provide colonization area for microorganisms.

- Pipes and tank walls: Biofilm formation with varying bacterial composition depending on flow velocity.

Microbiological Water Analysis

Practical monitoring of microbial populations:

- Redox potential measurement as an indicator of microbiological activity (optimal: 250-350 mV)

- Microscopic inspection of biofilm samples every 4-6 weeks

- Observation of sludge formation: Too little formation indicates insufficient microbiological breakdown

Disruptions in Microbial Balance

Practical problem indicators and countermeasures:

- Slimy biofilms: Often a sign of predominantly heterotrophic bacteria – increase aeration, reduce organic load.

- Odor development: Indication of anaerobic zones – mix substrate, optimize flow.

- pH drop below 6.0: Nitrification stalls – targeted addition of calcium carbonate.

Practical Nutrient Management

The balance between fish stock, plant quantity, and nutrient availability requires continuous adjustment:

Key Figures for Practice

| Parameter | Optimal Range | Measurement Interval | Corrective Measures for Deviation |

|---|---|---|---|

| Ammonium (NH₄⁺) | < 0.5 mg/l | Daily | Reduce feed amount, increase plant proportion |

| Nitrite (NO₂⁻) | < 1.0 mg/l | 2x weekly | Water change (10-15%), increase aeration |

| Nitrate (NO₃⁻) | 5-50 mg/l | Weekly | If too low: increase fish stock; If too high: increase plant proportion |

| pH Value | 6.5-7.0 | Daily | If decreasing: add calcium carbonate |

Practically Tested Plant Combinations

Experiences from systems recommend the following plant communities:

Herb Mixed Culture

Vietnamese Coriander (Persicaria odorata) with Thai Basil (Ocimum basilicum var. thyrsiflora) and Vietnamese Mint (Persicaria odorata).

This combination shows synergistic effects against pathogens and improves nutrient uptake from the water.

Vegetable Bed with Depth Effect

Horseradish (Armoracia rusticana) as a deep-rooter combined with New Zealand Spinach (Tetragonia tetragonioides) as a shallow-rooter.

Horseradish loosens the substrate through its root system and improves oxygen supply.

Shade-Tolerant Mixed Culture

Sweet Potato (Ipomoea batatas) as a climbing surface planting with Watercress (Nasturtium officinale) in the partially shaded area.

The sweet potato naturally shades the system and reduces algae growth.

Practical Tip: Crop Rotation

Establish a rotation system where approximately 30% of the planting is changed every 8-10 weeks. This prevents the depletion of specific nutrients in the water and reduces susceptibility to specialized pathogens.

Context:

The cultivation of medicinal plants in aquaponic systems requires specific knowledge about their nutrient requirements and growth conditions. This article examines the suitability of selected medicinal plants for cultivation in water recirculation systems.

Find more about medicinal plants in our separate article series on Medicinal Plants, Effects, Propagation, and Their Processing.

Specifics of Medicinal Plants in Aquaponic Systems

Medicinal plants have specific requirements for their growth conditions that must be considered when integrating them into aquaponic systems:

Advantages

- Precise control of nutrient supply

- Lower risk of soil contamination

- Controlled growth conditions

- Higher purity of active compounds

- Year-round cultivation possible

Challenges

- Species-specific nutrient needs

- Sensitivity to nutrient imbalances

- Differing pH requirements

- Varying tolerance to moisture

- Specific light needs

Suitability of Selected Medicinal Plants

Examination of the cultivation suitability of various medicinal plants in aquaponic systems:

Overview of Medicinal Plants and Their Suitability

| Plant | Suitability | Nutrient Requirement | Particularities |

|---|---|---|---|

| Stinging Nettle Urtica dioica |

Well suited | High (Heavy feeder) | Requires lots of nitrogen, thrives well in nutrient-rich water. Regular pruning required. |

| Echinacea Echinacea purpurea |

Limited | Medium | Sensitive to waterlogging. Requires well-aerated substrate. Perennial but winter-hardy. |

| Chamomile Matricaria chamomilla |

Well suited | Low to Medium | Annual, prefers moderate nutrient supply. Sensitive to excessively high nitrate levels. |

| Lavender Lavandula angustifolia |

Poorly suited | Very Low | Requires dry conditions and well-draining substrate. Sensitive to root rot in hydroponic systems. |

| Lemon Balm Melissa officinalis |

Very good | Medium | Grows excellently in hydroponic systems. Fast growth, regular pruning required. |

| Orange Mint Mentha × piperita citrata |

Very good | Medium to High | Robust, fast-growing. Requires sufficient space or isolation, as it spreads readily. |

| Peppermint Mentha × piperita |

Very good | Medium to High | Ideal plant for aquaponics. Fast growth, high water demand, tolerates various conditions. |

| Rosemary Rosmarinus officinalis |

Poorly suited | Low | Mediterranean plant with low nutrient demand and tolerance for drought. Prone to root rot in NFT systems. |

| Sage Salvia officinalis |

Limited | Low | Conditionally suitable. Requires excellent drainage and moderate moisture. Possible in media beds with coarse substrate. |

| Thyme Thymus vulgaris |

Poorly suited | Very Low | Mediterranean plant with high drought tolerance. Usually not successful in conventional aquaponic systems. |

Adaptations for Less Suitable Species

For Mediterranean herbs with low nutrient tolerance, special system adaptations can be made:

System Modifications

- Separate Loops: Creation of subsystems with reduced nutrient availability

- Drip Irrigation: Targeted, reduced irrigation for drought-tolerant species

- Substrate Selection: Use of coarse mineral substrate with excellent drainage

- pH Regulation: Targeted increase of pH for Mediterranean herbs

Nutrient Management

- Dilution: Targeted dilution of nutrient content for undemanding species

- Separate Feeding: Isolated nutrient supply for different plant groups

- Timed Supply: Intermittent nutrient supply for species with low demand

- Buffer Zones: Integration of plants with different needs into separate zones

Active Compound Content in Aquaponic Cultivation

Studies show varying effects of hydroponic cultivation on active compound contents:

Comparison of Active Compound Production

| Plant | Active Compound | Aquaponics vs. Soil Culture | Optimization Possibilities |

|---|---|---|---|

| Lemon Balm | Essential Oils | Higher concentration with moderate nutrient supply | Mild stress by reduced irrigation before harvest |

| Peppermint | Menthol | Comparable or slightly increased | Slight reduction of nitrogen supply before flowering |

| Echinacea | Alkamides | Variable, dependent on root health | Good aeration of the root zone crucial |

| Chamomile | Bisabolol | Higher values under controlled conditions | Even supply, no stress periods |

Practical Tips for Medicinal Plant Cultivation

Recommended Species for Beginners

- Peppermint - robust and adaptable

- Lemon Balm - fast growth

- Chamomile - moderate requirements

- Stinging Nettle - high nutrient tolerance

Harvest Optimization

- Harvest in the morning after the dew has dried

- Before full bloom for maximum active compound concentration

- Slight reduction of irrigation 24-48 hours before harvest

Note on Active Compound Quality

The quality of active compounds in medicinal plants is influenced by many factors. Aquaponic systems offer the possibility to control these factors precisely, but require exact knowledge of the specific needs of each plant species.

Context:

The successful operation of an aquaponics system requires continuous monitoring, preventive maintenance, and an understanding of scaling possibilities. This article highlights the practical aspects of system management.

Ongoing Operation: Monitoring Critical Parameters

Systematic monitoring is essential for the stable operation of an aquaponics system. An overview of the most important parameters:

Water Parameters

- pH Value (daily): Optimal range 6.5-7.0. A drop indicates nitrification processes, a rise indicates plant activity.

- Oxygen Content (continuous): At least 5 mg/l for fish, >6 mg/l for optimal bacterial activity.

- Temperature (daily): 18-24°C for mixed systems, species-specific adjustments possible.

- Conductivity (weekly): Indicator of total nutrient content, ideal 800-1200 µS/cm, which corresponds to 1.2 EC.

Nutrient Monitoring

- Ammonium (NH₄⁺): Daily check, should not exceed <0.5 mg/l.

- Nitrite (NO₂⁻): Twice weekly, limit <1.0 mg/l.

- Nitrate (NO₃⁻): Weekly, target range 20-50 mg/l.

- Redox Potential: Weekly, optimal 250-350 mV as an indicator of microbiological activity.

Maintenance and Fault Diagnosis

Preventive maintenance routines prevent system failures and guarantee long-term stability:

Maintenance Schedule

| Interval | Measure | Goal |

|---|---|---|

| Daily | Visual inspection of fish, plants, and technical components | Early detection of abnormalities |

| Weekly | Cleaning of pre-filters, checking pump performance | Prevention of clogging, ensuring water circulation |

| Monthly | Partial water change (10-15%), cleaning of biofilter surfaces | Reduction of pollutant accumulation, preservation of biofilm activity |

| Quarterly | Inspection of all hoses and connections, calibration of sensors | Prevention of leaks, ensuring correct measurements |

Common Problems and Solutions

- Algae Growth: Reduce light exposure, adjust nutrient levels, install UV clarifier.

- pH Drop: Dose calcium carbonate or potassium bicarbonate, increase aeration.

- Plant Diseases: Remove affected plants, check nutrient balance, add beneficial microorganisms.

- Cloudy Water: Improve mechanical filtration, reduce feed amount, install sludge separator.

Fish Health

Indicators for fish health:

- Active swimming behavior

- Consistent appetite

- Clear eyes and intact fins

- Balanced social behavior

If abnormalities occur: Check water parameters, reduce stress factors, establish quarantine if necessary. More on this in the article on stocking density.

Scaling Possibilities

Aquaponics systems can be adapted to various sizes and application areas:

Small Systems (Hobby Area)

Size: 1-2 m² growing area, 200-500 liter water volume

Suitable for: Herbs, salads, ornamental fish

Advantages: Low space requirement, easy maintenance, ideal for beginners

Recommended Technology: Air-pumped systems, manual parameter control

Medium Systems (Semi-professional)

Size: 5-20 m² growing area, 1000-5000 liter water volume

Suitable for: Vegetables, herbs, food fish

Advantages: Good yields, partially automated processes, educational projects

Recommended Technology: Automated aeration, pumps with timer, simple sensors

Large Systems (Urban Farming)

Size: 50+ m² growing area, 10,000+ liter water volume

Suitable for: Commercial food production, fish farming

Advantages: Economic yields, high automation, circular economy

Recommended Technology: Fully automated control, redundant systems, professional water treatment

Urban Farming Projects

The integration of aquaponics into urban spaces offers diverse possibilities:

Implementation Examples

- Rooftop Farms: Utilization of unused roof areas for food production with closed loops.

- Vertical Farms: Multi-level systems in urban areas with optimized space utilization.

- Educational Institutions: Integration into schools and universities to teach sustainable agriculture.

- Social Projects: Community gardens with aquaponics to promote local food production.

Outlook: Future of Aquaponics

The development of aquaponics shows promising trends for the future:

Technological Developments

- AI-supported monitoring and control systems

- Energy self-sufficient systems through solar and wind power

- Modular systems for easy scalability

- Improved sensor technology for more precise parameter control

Ecological Developments

- Integration of further loop components (insects, fungi)

- Regional adaptations with local species

- Improved closure of material cycles

- Combination with other sustainable cultivation methods

Practical Tip: Documentation

Keep a system logbook with all measurements, observations, and interventions. This documentation helps with fault diagnosis and optimization of processes over time.

Kontext:

The stocking density of fish in aquaponic systems is subject to legal requirements and biological limits. This article explains the legal framework and practical recommendations for species-appropriate husbandry.

Legal Basis: REGULATION (EC) No 710/2009

The European Union regulates organic aquaculture in Regulation (EC) No 710/2009. These requirements are binding for all operations that wish to market their products as organic.

Application Note

The specified stocking densities represent maximum values. In practice, lower densities should be aimed for to ensure the stability of the aquaponic system and the well-being of the fish.

Stocking Densities according to EU Organic Regulation

The maximum permitted stocking densities for different fish species in closed recirculating systems:

Overview of Maximum Stocking Densities

| Fish Species | Scientific Name | Max. Stocking Density | Particularities |

|---|---|---|---|

| Brook Trout | Salvelinus fontinalis | 15 kg/m³ | Requires cool, oxygen-rich water |

| Whitefish (Coregonus) | Coregonus spp. | 15 kg/m³ | Demanding regarding water quality |

| Trout (general) | Oncorhynchus, Trutta | 15 kg/m³ | Well suited for cooler systems |

| Arctic Char | Salvelinus alpinus | 20 kg/m³ | More robust than Brook Trout, tolerates slightly higher densities |

| Brown Trout and Rainbow Trout | Salmo trutta fario, Oncorhynchus mykiss | 25 kg/m³ | Most commonly used species in aquaponics systems |

| Salmon (various) | Salmo trutta (various subspecies) | 20 kg/m³ | For larger systems with stable conditions |

| Milkfish | Chanos chanos | 10 kg/m³ | For warmer systems, brackish water possible |

| Tilapia | Oreochromis spp. | 10 kg/m³ | Popular species for warm systems, robust |

| Pangasius Catfish | Pangasius spp. | 10 kg/m³ | Fast-growing, for warmer systems |

Practical Implementation of Stocking Densities

The legal requirements are maximum values. In practice, various factors should be considered:

Recommended Practical Values

For stable aquaponic systems, the following stocking densities are recommended:

- Initial Stocking: 30-50% of the permitted maximum density

- Established System: 60-80% of the permitted maximum density

- Optimal Performance: 5-10 kg/m³ for most species

Lower densities increase system stability and reduce disease risk.

Risks of Excessive Stocking Densities

- Increased oxygen demand

- Faster accumulation of metabolites

- Higher stress load for the fish

- Reduced resistance to diseases

- Less stable nutrient ratios for the plants

Calculation of Stocking Density

Stocking density is calculated based on the total system volume:

Calculation Formula

Stocking Density (kg/m³) = Total Fish Weight (kg) / System Water Volume (m³)

Example Calculation:

- System water volume: 2 m³ (2000 liters)

- Target stocking density: 10 kg/m³

- Maximum fish weight: 20 kg

Practical Tip

Consider the expected final weight of the fish for the calculation, not the initial stocking weight.

Adjustment Factors for Practice

Optimal stocking densities can vary depending on system characteristics:

Factors for Higher Densities

- Highly efficient oxygen injection systems

- Excellent filtration performance

- Low temperature fluctuations

- Experience in system management

- Redundant system components

Factors for Lower Densities

- Limited oxygen supply

- Restricted filtration capacity

- High temperature fluctuations

- Limited experience with the system

- Sensitive fish species

Monitoring at Different Stocking Densities

Monitoring should be adapted to the stocking density:

Monitoring Parameters

| Parameter | Low Density (<10 kg/m³) | Medium Density (10-20 kg/m³) | High Density (>20 kg/m³) |

|---|---|---|---|

| Oxygen Content | Daily check | Several times daily | Continuous monitoring |

| Ammonium/Nitrite | 2x weekly | 3x weekly | Daily |

| pH Value | Daily | Daily | Several times daily |

| Fish Behavior | Daily observation | Several times daily | Several times daily |

Important Note

The values provided here are based on REGULATION (EC) No 710/2009. Please note that national regulations may impose additional restrictions. Always inform yourself about the local legal requirements before setting up an aquaponic system.

Context: