|

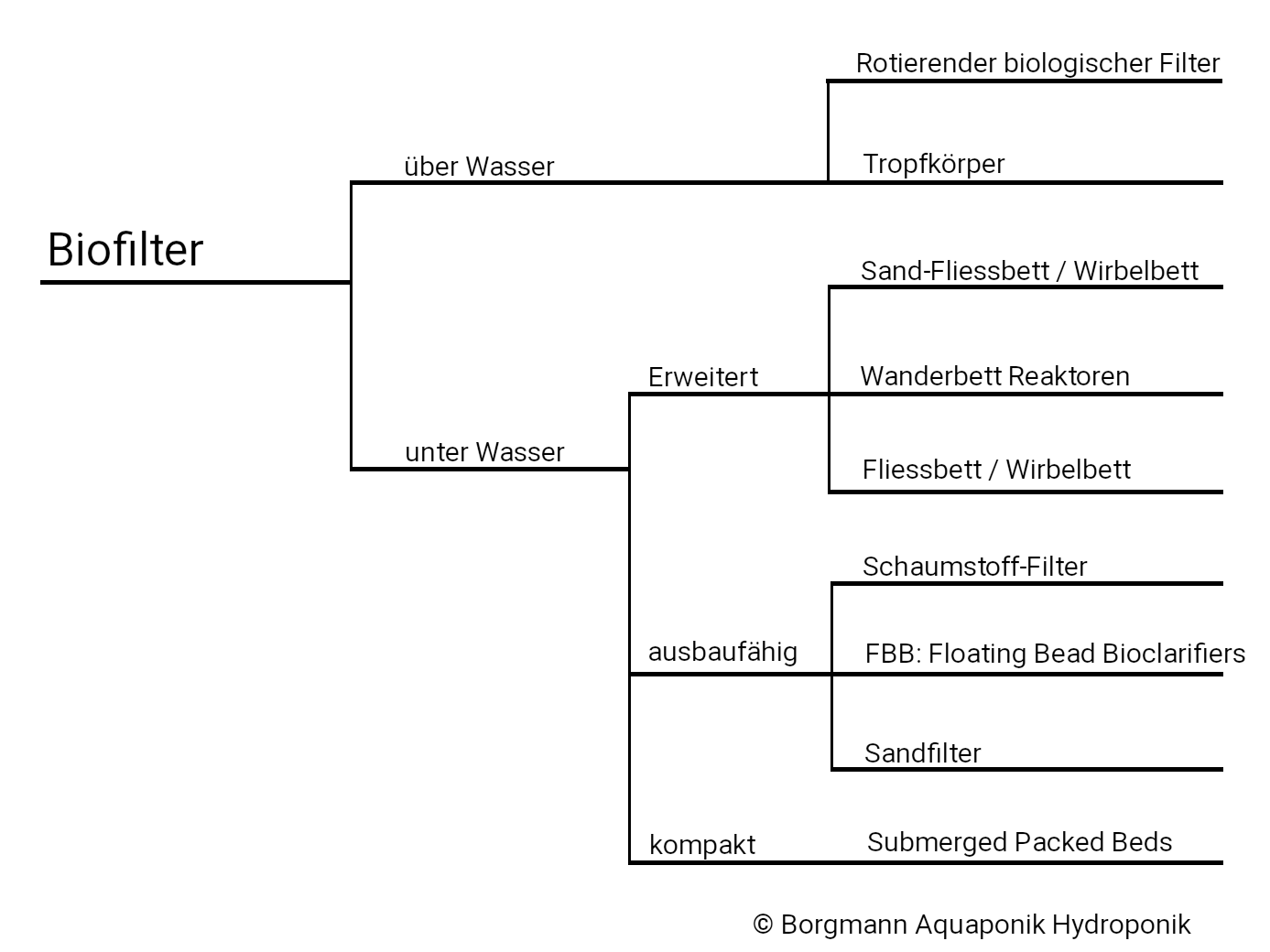

The heart of an aquaponics system is its biofilter. The heterotrophic and autotrophic Bacterial communities in the biofilter naturally process organic waste and deliver biologically stable water that can be recycled for months. When choosing a biofiltration system for commercial aquaculture production, the efficiency of the technology and the substrate are very important because they determine the size, cost and energy consumption of the most expensive treatment components in circulatory systems. Figure: Aquaculture engineers have to make a number of decisions when choosing the best biofilter for a particular application. Successive decisions at each node of the "decision tree" lead to the most reliable and cost-effective filter. FBBs ( Floating Bead Bioclarifiers ) offer better solids separation ( 100% up to 30 µm ) as micro sieves and sedimentation tanks and at the same time avoid the problem of baking, which is typically associated with sand filters under high organic loads.

Under water or over water ? Aerobic filters require oxygen. If the biofilm in the water that is transported to the filter can be adequately supplied with oxygen, choose an underwater filter. Otherwise, you should choose an ascending filter. Emergent (ascending) filters (EGSB) use a cascade-shaped mixture of water and air to ensure that a high oxygen content is maintained on the surface of the biofilm. Drip bodies distribute the water via a column filled with biofilter media. Rotating biological contactors - sometimes called wet / dry filters - use a more mechanical approach. They slowly turn into a water tank and out again, whereby the medium always stays wet, but is additionally aerated.

Overwater filter Emergent filters are able to achieve an extremely high area conversion of TAN (converted TAN in grams per square meter surface), are limited by a small specific surface area (square meters of biofilm per cubic meter of unit volume). As a result, emerging filters can be 5 to 10 times larger than the submerged alternatives, and caution should be exercised with some media types to prevent possible constipation. These filters offer secondary benefits in the form of ventilation and carbon dioxide stripping. They are best suited for heavily loaded systems, where their ability to supply oxygen to the biofilm can bring some benefits. TAN: Total ammonia nitrogen / total ammonia nitrogen

Underwater filter Proponents of immersion filters point out that the fish live in circulatory systems on the inlet side of the filters and that the TAN values have to be kept very low. They argue that it is not oxygen diffusion, but TAN diffusion in biofilms that limits the performance of biofiltration. Proponents of underwater filters usually focus first on maximizing the specific surface and then on biofilms and solids management to improve TAN diffusion rates.

Underwater pouring bed The oldest biofilters consist only of a bed of submerged media through which the water is circulated. These filters generally have no biofilm or solid management functions, and little attention is paid to the specific surface. These filters are used with great success in husbandry systems for seafood, lightly polluted aquaculture, show aquariums and the like. The large, inexpensive filters do a good job until they are overloaded and get into a zone with positive bacterial growth that makes them unusable because no more water can penetrate the filter. These shortcomings in dipped bulk beds have been remedied by filters that can deal with the problem of solids accumulation.

Expandable granulate filters Expandable granulate filters differ from other filter types by a backwash mechanism. Expandable granulate filters, which include fine sand filters, gravel filters and bead filters, have a similar backwash strategy that enables them to work in a wide range of functions. This choice controls water loss and has a major impact on how easily the filters' biofilms can be manipulated. Expandable granulate filters have the unique ability to work as mechanical filters, biofilters or bioclars. However, their effectiveness in these three areas is very different.

Fine sand filter Fine sand filters are mainly used as mechanical filters in most applications, but contribute to a certain nitrification in circulatory systems. These filters are poorly suited as biofilters in most commercial applications because the development of a biofilm quickly overrides the washing mechanism. All sand and gravel filters require high flow rates to start their expansion, which also leads to high water losses during backwashing. These water losses can hinder biofilm management strategies that improve the performance of biofilters. Sand filters are often used as sewage treatment tanks for show aquariums, as mechanical inlet filters in aquaculture systems and as biofilters in very weakly loaded circulatory systems.Coarse sand and gravel media are used with some success because they have sufficient abrasion capacities to cut off organic flakes and to avoid the problems of baking that plague finer sandbeds.

Floating bead filter Floating-bead filters have practically all the properties of sand and gravel filters, but reduce or eliminate the problems of biofouling and water loss. Depending on the application, bead filters can be used effectively as mechanical filters, biofilters or bioclars, at the same time intercepting solids and acting as biofilters. The backwash mechanism and the frequency of backwash of the plants are used as an instrument for managing the biofilm. Well-managed plants are therefore able to achieve volumetric TAN conversion rates that are highly competitive with other biofiltration formats. In addition, the water loss for these filters is between just over 1 percent and 10 percent of the backwash requirement for equivalent gravel filters.

Expanded biofilters Expanded biofilters, in which sand or pearls are continuously expanded, do not catch any solids, but are used as highly effective biofilters. Biofilter with fluidized sand bed keep the sand particles in suspension evenly so that the medium behaves like a liquid. The extremely high specific surface of the fine sand medium enables the filters to operate effectively at low ammonia values of less than 0.1 mg-N per liter, even if they are exposed to unfavorable conditions such as low pH. Fine sand particles are best suited for lightly stressed systems in which very low TAN concentrations are required. For example, they are used with great success in the ornamental fish industry. However, the units tend to lose sand when the substrate content increases,and are only able to remove biofilm to a limited extent.

Coarse sand Coarse sand filters still have an excellent specific surface, are very abrasive and are well suited for higher loading capacities. Coarse sand vertebral layers support very high TAN conversions, but usually only with increased ammonia values of more than 1.5 mg-N per liter. The biofilm is overused at low substrate concentrations.

The filter ... which is not one This is not a filter in the strict sense, since the main purpose is to separate gaseous or dissolved substances and not solid particles. In contrast to the biodiesel bed reactor, on the one hand, in which a so-called biological lawn forms on installations in the reactor, which is continuously flushed, and the bio-washer on the other hand, in which the microorganisms are predominantly suspended in a washing liquid, the microorganisms in the biofilter are fixed on a matrix that partially provides the nutrient supply. The idea of cleaning exhaust air and waste water biologically already existed in the 1920s, and technical use took place in the 1960s at the latest. Over the years, biofilters have been optimized for a variety of applications.

Function On the one hand, a biofilter filters physically undesirable solids and, on the other hand, it transforms with the help of microorganisms, among other things. the ammonia from the fish excretions into nitrate, which can therefore be used by the plants as fertilizer.

Mechanical filtering In addition to water, solid excretions of the fish, feed residues or algae are pumped into the plant beds from the fish tank. So that the substrate of the filters does not clog, worms must either ensure that these solids are converted or the solids must be removed mechanically beforehand.

Depending on the system design, there is also a sedimentation basin (also called a sedimentation system). This is an almost flow-free basin, in which water constituents are sedimented by gravity and thus a separation of removable substances from a liquid can be achieved. Here the water speed is reduced to such an extent that suspended matter can settle at the bottom. From there they can be removed with a mulm vacuum cleaner or a mechanical rake.

Recycling of suspended matter by worms Since nutrients are also contained in the suspended matter, it is of course better (and easier) to use them. That is why worms are placed in the plant beds. Not all worms are equally suitable for this purpose. The typical „ earthworms “ from the garden need different soil depths than we can provide in aquaponics. Redworms (Eisenia foetida, Eisenia andrei, Dendrobena veneta), which are sold for worm compost or as fishing bait, are well suited. Permanent flooded plant beds with a simple overflow are not suitable for the use of compost worms. Regular flooding in pumped systems, on the other hand, does not harm the worms.

Chemical filtering The substrate also forms the habitat for the bacteria, which convert ammonia excreted by the fish into nitrate in a two-stage process. The first step of this so-called nitrification takes place aerobically ( in an oxygen-containing environment ) as oxidation of the ammonia to nitrite by nitrite bacteria. In the second process step, nitrate bacteria convert nitrite into nitrate by oxidation. These bacteria also live aerobic, so they need oxygen. If the filters clog through suspended matter, anaerobic zones arise in which the bacteria in the nitrification process die and use anaerobic putrefaction processes. The water receives the oxygen by pumping into the substrate and with compressed air that is added.

Effect of nitrate Nitrate is an important plant fertilizer that mainly produces leaf growth. For salads, this is desirable to a certain extent. Amounts of nitrate that are too high are deposited in the leaves and are absorbed in the body when consumed. Nitrate and nitrite are suspected by converting them into the stomach and intestines, among others. Nitrosamines to be carcinogenic.

Environmental conditions A product of nitrification is acid, so water in the cycle can increasingly acidify. However, the bacteria in the biofilter need a basic to neutral environment, which is why countermeasures to stabilize the pH value must be taken as part of regular maintenance. Depending on the season and latitude, attention must be paid to the temperature. Depending on the microorganisms used, temperatures of 40 should be minimal0 Celsius should never be exceeded. Even under 10° Celsius some bacteria slow down their work to such an extent that they are no longer useful. From 0 ° Celsius, the bacteria in the biofilter die. Such a system must always be "run in !

One more word about TAN (Total ammonia nitrogen / total ammonia nitrogen) Quantification of nitrification In the past, studies have shown nitrification rates based on the specific surface of the media, with higher SSA values being preferred. Theoretically, the larger the SSA, the more habitat for bacteria. In an ideal world, this would lead to higher nitrification rates. In the real world of commercial aquaculture, however, the bacteria form a biofilm that can effectively cover the medium, possibly in a way that clogs the topographical or porous features of the medium, which are intended to enlarge the specific surface. This covering of the medium essentially creates a new media topography and reduces the surface actually used by the bacteria.

Volumetric TAN conversion rate Therefore, the theoretical nitrification capacity of a certain filter medium based on the SSA does not always reflect the nitrification actually achieved in the real world. It was recently suggested, that the nitrification rates of biofilters should be based on the TAN conversion per unit volume of the non-expanded filter medium. Designated as the volumetric TAN conversion rate ( VTR ), typical units for this standard measure of nitrification are grams of TAN removed per cubic meter of biofilter medium per day. |

Biofilter (en)

Context:

ID: 159

- Details

- Category: Technology

-

Also available: